Piedmont Pipe Manufacturing delivers a lighter, more durable, and easier-to-use product that’s more cost-effective for your project: stainless steel downspout connectors. Our units come standard with mounting hardware, cleanout ports, and a durable powder coat finish to help them blend seamlessly into your construction.

Features and Benefits

Patented Features

Only Available from Piedmont Pipe Manufacturing

Piedmont Pipe Manufacturing downspout connectors are anything but standard with truly unlimited sizing and style options.

Our Debris Evacuation Cleanout provides an internal 304 stainless steel grate and a hinged evacuation door to eject roof debris out of the downspout system before it can make it into the underground piping. This feature is excellent in heavily wooded areas or on public and educational facilities where rocks, balls, bottles, and other large debris can collect in the gutter and clog the underground piping in large rain events.

Customizable Cleanout Ports Standard

- Cleanout access on the body of the downspout connection allows for pipe maintenance as needed.

- Eliminate the need for in-ground cleanouts on the roof drain leader piping vs. in-ground PVC cleanouts that are often overgrown and lost or have become broken, safety hazard within the first five years of installation.

- Cleanouts may be offered by most manufacturers of cast iron products but are not standard and substantially increase the costs of the units.

- Excludes the A1 & A2 transition adapter and SG above-ground outlet models

True Full-Sized Bodies

Some cast iron manufactures advertise a full range of sizes, but this is accomplished by providing large connection inlets attached to standard sized bodies. For instance, a 5”x7” inlet may be connected to a 5”x 6” body.

Custom Rolled “Stab-fit” Vertical Outlets

- Sized to fit the internal dimension of any size and type of pipe. “Stab-fit” outlets are supplied with a “trim ring” to conceal the pipe profile at finished grade, providing a clean finished look in paved areas.

- Allows for more protection above grade, or for the unit to be shortened while providing the same exposure height of longer units connecting below grade.

- Eliminate the need for ugly external coupling at or above finished grade

- Allow for boot installation after concrete, asphalt or landscaping has been completed.

Superior Materials

Piedmont Pipe Manufacturing products are available with a factory-applied, durable powder coat finish that’s UV-resistant and made for exteriors. While attractive on a building, our products are also made from nearly-indestructible stainless steel and aluminum so the beautiful finish is strictly for aesthetics.

Piedmont Pipe Manufacturing downspout connections are entirely manufactured from 12ga. 304 stainless steel or 11ga. aluminum plate.

Stainless Steel Stands Up

- Stainless steel and aluminum won’t rust like cast iron products even in the toughest conditions.

- Stainless steel and aluminum won’t crack at impact, unlike brittle cast iron or PVC products.

- Stainless steel is the perfect material for direct encasement in concrete.

Modern Design & Fabrication Means Smart Spending

- On most units, there are no visible external mounting points providing a clean finished look with no rusting mounting hardware.

- Aluminum, stainless and carbon steel offers a lower cost-per-unit when compared to comparable cast iron products.

- Aluminum and Stainless steel is virtually maintenance free forever.

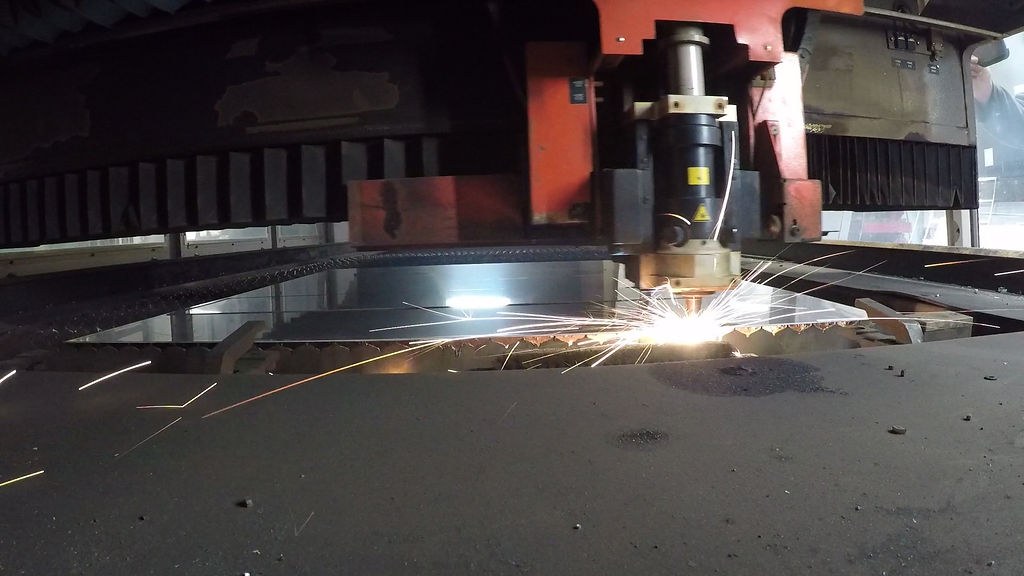

- Piedmont Pipe Manufacturing products are manufactured using the latest in CAD design, laser cutting, and robotic welding.

- There are no limits to the size or shape of the units Piedmont Pipe Manufacturing can provide for your custom projects – our sizing is truly unlimited.

- Piedmont Pipe Manufacturing ships your order within days of receiving it, no matter what the size or shape.